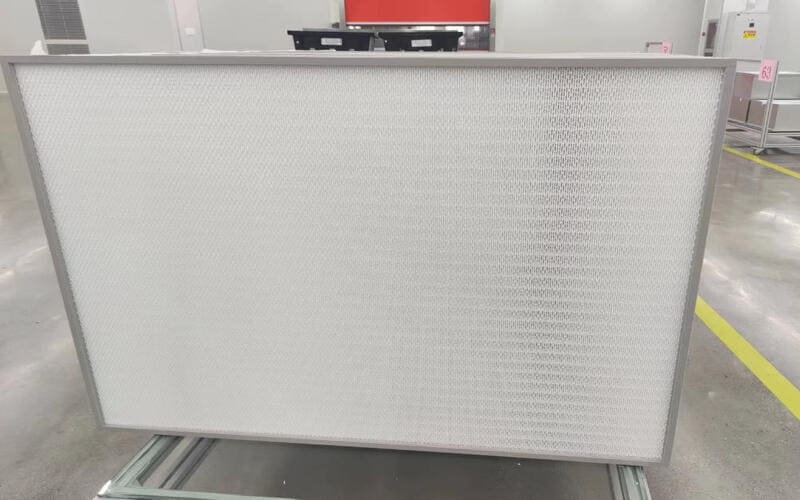

Komtfil ULPA Filters deliver ultra-clean air filtration designed for critical environments requiring the highest standards of air purity. Engineered for maximum efficiency and durability, these filters meet the stringent demands of industries such as pharmaceuticals, semiconductor manufacturing, and healthcare.

ULPA (Ultra Low Penetration Air) filters are advanced air filters capable of removing at least 99.9995% of airborne particles as small as 0.12 microns. They are a step above HEPA filters, targeting ultra-fine particle filtration to ensure superior contamination control. Key characteristics include:

Comparison with HEPA and Other Filter Types

| Feature | HEPA Filters | ULPA Filters |

|---|---|---|

| Filtration Efficiency | 99.97% at 0.3 microns | 99.9995% at 0.12 microns |

| Particle Size Captured | Particles ≥ 0.3 microns | Particles as small as 0.12 microns |

| Application | General cleanroom and HVAC | Critical cleanrooms and sterile environments |

| Typical Use | Residential to commercial | Pharma, semiconductor, medical |

ULPA filters use ultra-low particulate arresting technology to trap the tiniest contaminants—down to 0.12 microns and smaller. Unlike regular filters, Komtfil ULPA filters capture ultra-fine particles like microscopic pathogens, nano-sized dust, and other airborne pollutants with efficiency reaching up to 99.9995%.

Here’s how it works:

In short, Komtfil ULPA filters provide unmatched protection by removing nearly all airborne contaminants, ensuring the cleanest air possible for sensitive spaces.

Komtfil ULPA filters deliver top-notch air quality by capturing ultra-fine particles down to 0.12 microns with 99.9995% efficiency. This means cleaner, safer environments, whether you’re running a cleanroom, hospital, or high-tech facility.

Here’s what you get with Komtfil ULPA filters:

Traps microscopic pathogens, dust, and industrial pollutants to keep your air almost particle-free.

Durable filter media and sturdy frames mean less frequent replacements and reliable performance over time.

Designed for optimized airflow that reduces pressure drop—lowering your energy costs without compromising filtration.

Available in common sizes (12″x12″, 2’x4′, 2’x3′, etc) with gasket seals for airtight fitting. Maintenance is straightforward, saving technician time.

Reduced replacement frequency plus energy savings result in lower total cost of ownership.

Komtfil ULPA filters are built to deliver ultra-clean air in places where air quality is critical. Here’s where they work best:

Cleanrooms in Pharma, Semiconductor, and Biotech

These filters maintain strict contamination control, keeping microscopic particles and pathogens out to protect sensitive processes.

Hospitals and Medical Facilities

ULPA filters help reduce airborne bacteria and viruses, creating safer environments for patients and staff.

Industrial Manufacturing and Electronics Assembly

They prevent dust and ultra-fine particles from damaging delicate components, ensuring high product quality.

Laboratories and Research Centers

Keeping air ultra-pure is key for accurate tests and experiments, which Komtfil ULPA filters handle reliably.

HVAC Systems Needing Ultra-Clean Air

For buildings that demand top-notch air purity, these filters fit perfectly, improving overall indoor air quality without sacrificing airflow.

No matter the environment, Komtfil ULPA filters provide the dependable particle filtration needed for critical air cleaning applications.

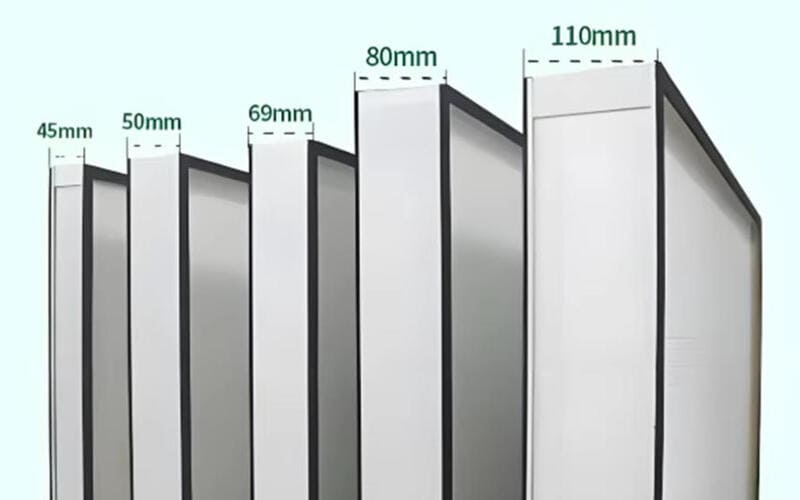

We offer flexible customization to fit your exact needs. Whether you require unique sizes or specific frame materials, we can tailor our ULPA filters to match your setup.

This flexibility ensures your Komtfil ULPA air filter works efficiently with your system, providing the ultra-clean air quality you expect without compromise.

Komtfil ULPA filters provide exceptional filtration performance with an efficiency of 99.9995% at 0.12 microns. This makes them ideal for capturing ultra-fine particles, including microscopic pathogens and contaminants.

Filter Media and Technology

Dimensions and Airflow Ratings

| Size Options | Airflow Rating (CFM) | Typical Pressure Drop (in. Pa) |

|---|---|---|

| 12″ x 12″ | Varies by model | Low to moderate |

| 2′ x 2′, 2′ x 3′, 2′ x 4′ | 200 to 600 | 100 to 200 |

| 16″ x 24″, 16″ x 36″, 16″ x 48″ | Custom airflow ratings | Based on application |

Pressure drop is optimized for energy-efficient operation without sacrificing filtration quality.

Frame Materials and Design

Certification Standards

Komtfil ULPA filters meet and exceed industry standards:

These specifications guarantee that Komtfil ULPA filters deliver reliable, certified performance for the most demanding clean air needs.

Choose Komtfil ULPA filters to maintain ultra-clean air with dependable performance and lower operating costs.

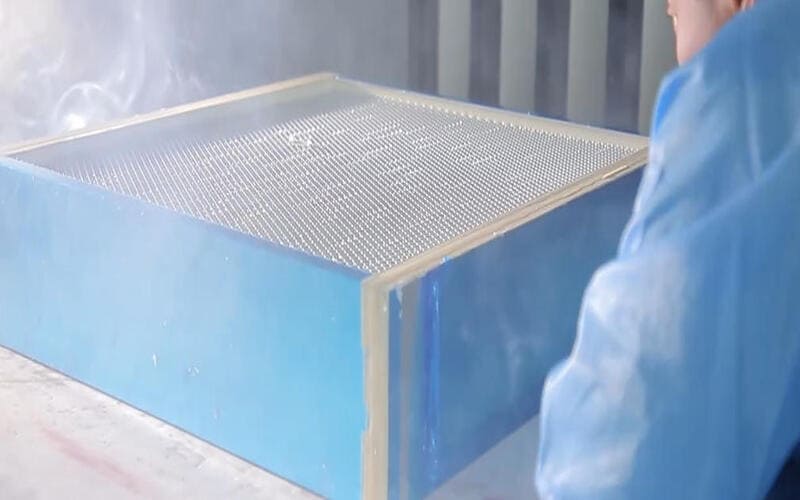

Komtfil ULPA filters meet all key industry standards to guarantee top performance and safety. Our filters comply with IEST, ISO 29463, RP-CC034, and EN 1822, ensuring they reliably filter out 99.9995% of particles as small as 0.12 microns. This level of certification meets or exceeds the U.S. market’s demands for critical environments, such as cleanrooms, hospitals, and laboratories.

We follow strict quality assurance protocols. Every batch undergoes rigorous testing to verify filtration efficiency, airflow, and pressure drop, so you get consistent, trusted results. Our manufacturing process uses thermoplastic resin separators and microfine glass media packs, which meet regulatory specs for durability and performance.

For customers requiring EPA, HEPA, or ULPA filters with proven traceability and certified specifications, Komtfil provides peace of mind with fully documented test results and product certifications. This makes it easier for you to meet compliance when working in highly regulated industries or demanding clean air applications.

At Komtfil, we stand behind our ULPA filters with dedicated customer support to help you get the most from your purchase. Whether you need guidance on installation, maintenance, or troubleshooting, our team is ready to assist you quickly and professionally.

To reach our support team, you can contact us via phone or email. We respond promptly to inquiries, helping you resolve issues or answer questions about Komtfil ULPA air filters, compatibility, or replacement procedures. Our goal is to provide reliable, ongoing assistance throughout the product lifecycle.

Ordering Komtfil ULPA filters is straightforward and designed to fit your needs. You can place orders by contacting our sales team for personalized assistance. Whether you need standard panel types, box types, or custom sizes, we have options ready for quick processing.

Shipping and Delivery

Fast shipping across the world with reliable carriers

Options for expedited delivery if your project timeline is tight

Secure packaging to protect your ULPA filter media and frames during transit

Tracking available from shipment to delivery

Bulk Orders and OEM Partnerships

Competitive pricing for large volume purchases

Custom packaging and labeling available for OEM clients

Flexible MOQ (Minimum Order Quantities) to suit both small businesses and large manufacturers

Dedicated support for ongoing bulk orders and repeat contracts

Get in touch with Komtfil for a quote or to discuss your specific ULPA filter requirements. We make sure you get the right filters on time and at a great value.

Our ULPA filters are ideal for environments that need ultra-clean air, like cleanrooms, pharmaceutical facilities, labs, and hospitals. They trap ultra-fine particles down to 0.12 microns with 99.9995% efficiency, making them perfect where contamination control is critical.

Replacement depends on usage and air quality but typically ranges from 12 to 24 months. Monitor pressure drop increases or any airflow reduction as signs it’s time to swap filters.

Yes, our ULPA filters come in standard sizes like 12×12, 2×4, and custom frames to fit most HVAC systems requiring ultra-low penetration air filtration. Proper sealing and compatibility checks ensure optimal performance.

Yes, they are designed with optimized airflow dynamics and low pressure drop to reduce energy consumption over their lifespan.

If problems persist, our customer support team is ready to assist with detailed guidance.

Komtfil is dedicated to air filtration and sustainable development. We offer comprehensive air filtration solutions to help you achieve success. Whether for home, business, or industry, our expert solutions will significantly improve your air quality.